Extraction of Iron from its ores, Iron dressing, Reduction ...

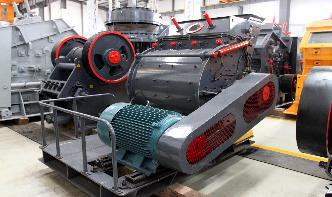

· Crushing process is used to obtain iron ore in small size that can be reduced easily, ... After the reduction of iron ores in the blast furnace or Midrex furnace, the third step in which the production of different types of iron such as cast iron and steel, The steel industry depends on two essential processes: Removal of unwanted impurities from iron resulting from .