What Is Toll Milling/Grinding? | Particle Control

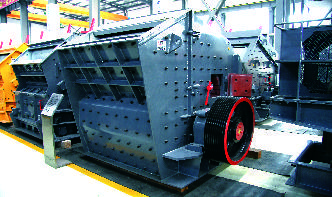

Toll milling/grinding is when a company offers milling or grinding of materials as a service for another company who, in return, pays a fee or "toll". "Milling" is essentially grinding and is used to reduce the size of a material, powder, particles, etc.