Iron Ore Pelletizing Process: An Overview

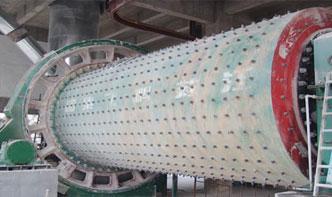

Pellets are balls formed by rolling moist concentrates and fines iron ores of different mineralogical and chemical composition, with the addition of additives and binder, in a horizontal drum or in an inclined disc [1, 4]. Product Size range (mm) Basic appliion Lump Directly fed to blast furnace and direct reduction Sinter feed Agglomeration by sintering to be fed in ...