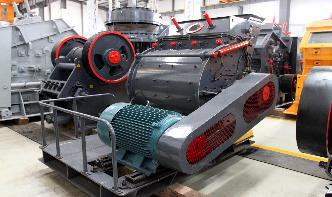

NETZSCH Premier Technologies

NETZSCH Premier Technologies, LLC is the North American subsidiary of the globally operated group of NETZSCH companies. NETZSCH is a leading manufacturer of wet grinding and dispersing machinery, including media milling, dispersing and deaerating from lab research to fullscale production in the following appliions: Agriculture. Adhesives.