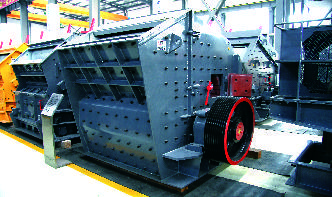

Hammer mills: hammermills

Optimal hammer design and placement will provide maximum contact with the feed ingredient. Hammer mills in which the rotor speed is approximately 1,800 rpm, should be using hammers which are around 25cm (~ 10 inches) long, (~ inches) wide, and ( inches) thick. For a rotor speed of about 3,600 rpm, hammers should be 15 to 20 ...