basket mill batch grinding for pigment emulsion

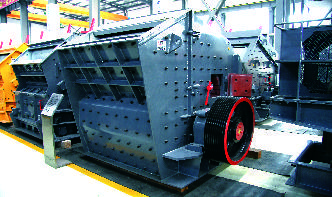

Module: 11 Lecture: 45 nptel of paint is the dispersion of pigment particles (often mixed with extenders) in a paint ... After grinding, the mill base is mixed with other paint ingredients, vehicle ...Bead mill. Basket mill. High speed disc disperser etc. Ball mills are ... Conventional vertical sand mills were invented to get around the batch size.