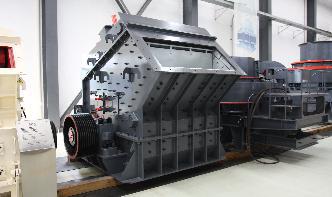

Iron Ore Beneficiation Jig Machine

The structure of iron ore decides beneficiation method of iron ore. Generally, magnetite iron is upgraded by magnetic separation with machines of crushers, ball mills, magnetic separators involved while for weak magnetic iron ore is beneficiated by intensity magnetic separation and gravity separation to get high grade iron concentrate with machines of crusher, ball mills, intensity magnetic ...