Halliburton Barite Grinding Plant Construction

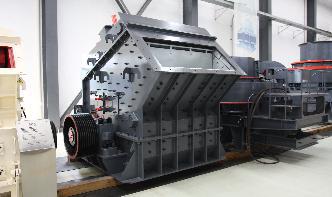

Barite Grinding Plant Halliburton Dunphy, Nevada Based on the success of the barite grinding facility designed and built by Mouat in Larose, Louisiana, Halliburton contracted Mouat for the turnkey design and construction of their most recent mineral processing plant loed in Dunphy, Nevada. This plant was started up in the spring of 2014.