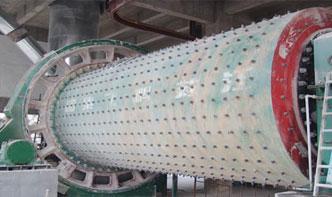

Copper Ore Processing Plant

Copper Ore Processing PlantHengcheng offers turnkey solutions for Copper flotation Plant. We are one of the leading project suppliers for Copper flotation Plant and we work closely with our customers to fulfill their specific needs for customized package solution. Specialized in the fabriion of these machines for 15 years and this enables us to